Day 2 - April 9th

Beginning Equipment training

- Schedule Coordination

- Mini Design Challenge

- Lab Tours

- General Shop Safety Rules

- Sign In, Turn in Cellphones

- Custom Schedule Passout

- Discuss Folders, Design Notebooks, USB Keychains

- Create Fusion 360 Accounts

- Complete Surveys

- Summary of Equipment Trainings

- Break into 3 training groups:

Surveys

To get a sense of student experience and mindset going into the course:

(Please use your pcc email when filling out surveys)

Equipment:

The most commonly used tools in this course are the 3D Printer, CNC Router, & Laser Cutter, so we are doing a crash course this week on all three, to ensure that everyone is familar with the equipment before moving forward.

There is a lot you can learn about all these tools and we do not expect you to absorb all the information we are giving you today. Most of this knowledge you will gain slowly over time, through repeated use of the equipment.

Equipment Guides

These Equipment Guides offer a Summary of the Important Functions, features, and Safety Protocols for each piece of equipment. It is recommended that you reference these when youa are getting started, and suppliment with additional resources as necessary.

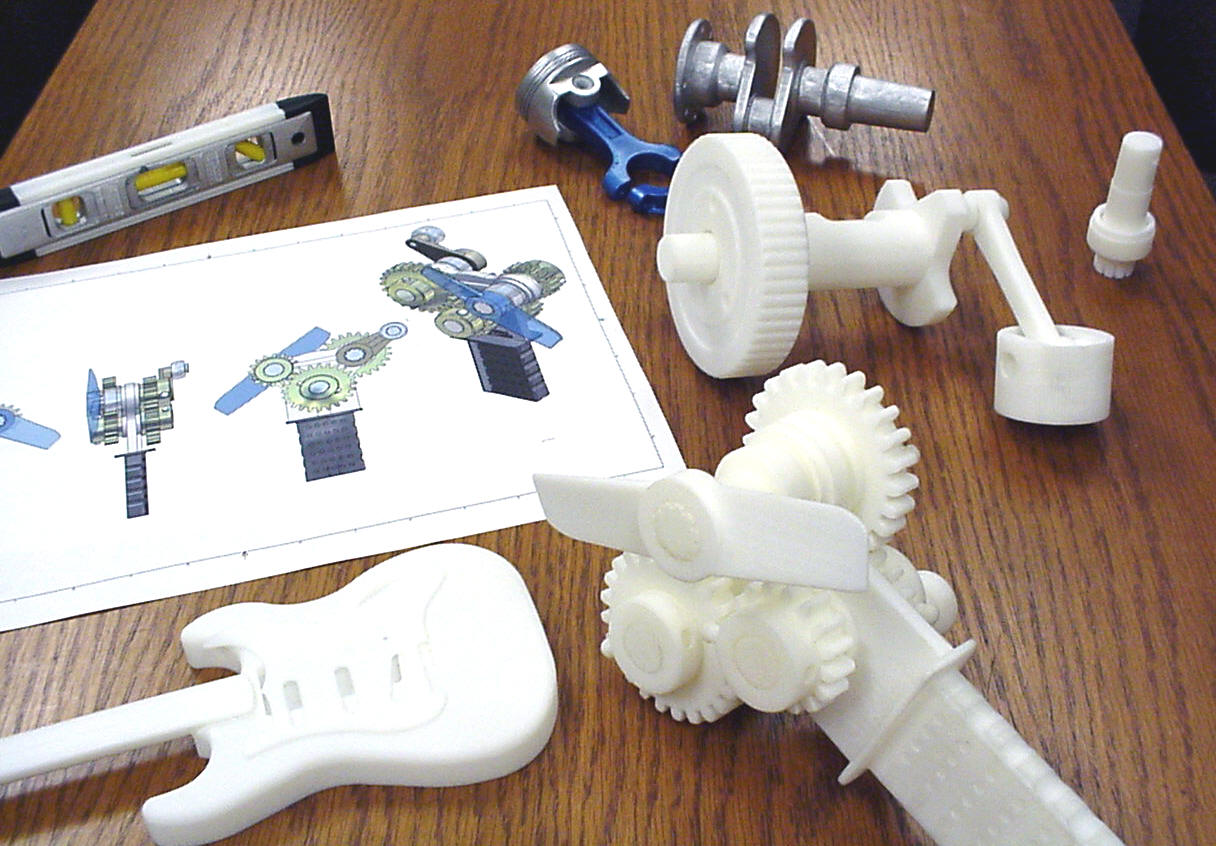

3D Printing

What is 3D Printing?

3D Printing is an additive manufacturing technique where a material is applied in layers by a machine running a computer generated toolpath (unlike traditional machining, where stock is carved away at to produce a final geometry). This toolpath is derived from a 3D model, a geometry defined entirely on the computer by a user working in a modeling program.

There are many different types of 3D Printers, today we will be working with a common type called a Filament printer, which extrudes melted plastic as its additive material.

Some info in 3D Printers

- 3D Printing Wiki

- 3D Printing Intro Video

3D Modeling Tutorials

The 3D Modeling program we will be using is called Fusion 360. It is cloud-based and free to students, so you can continue designing with the program once the course is over.

Using Cura

After a 3D model is created, a toolpath specific to the user’s 3D printer has to be generated, with the help of a slicing program which breaks the model into the individual print layers and builds out a path for the printer to take. We will be using Cura, another free program.

3D Model Sources

Many people generate and share 3D models that you can download, modify, and print on your 3D Printer.

Thingiverse is a popular model sharing site.

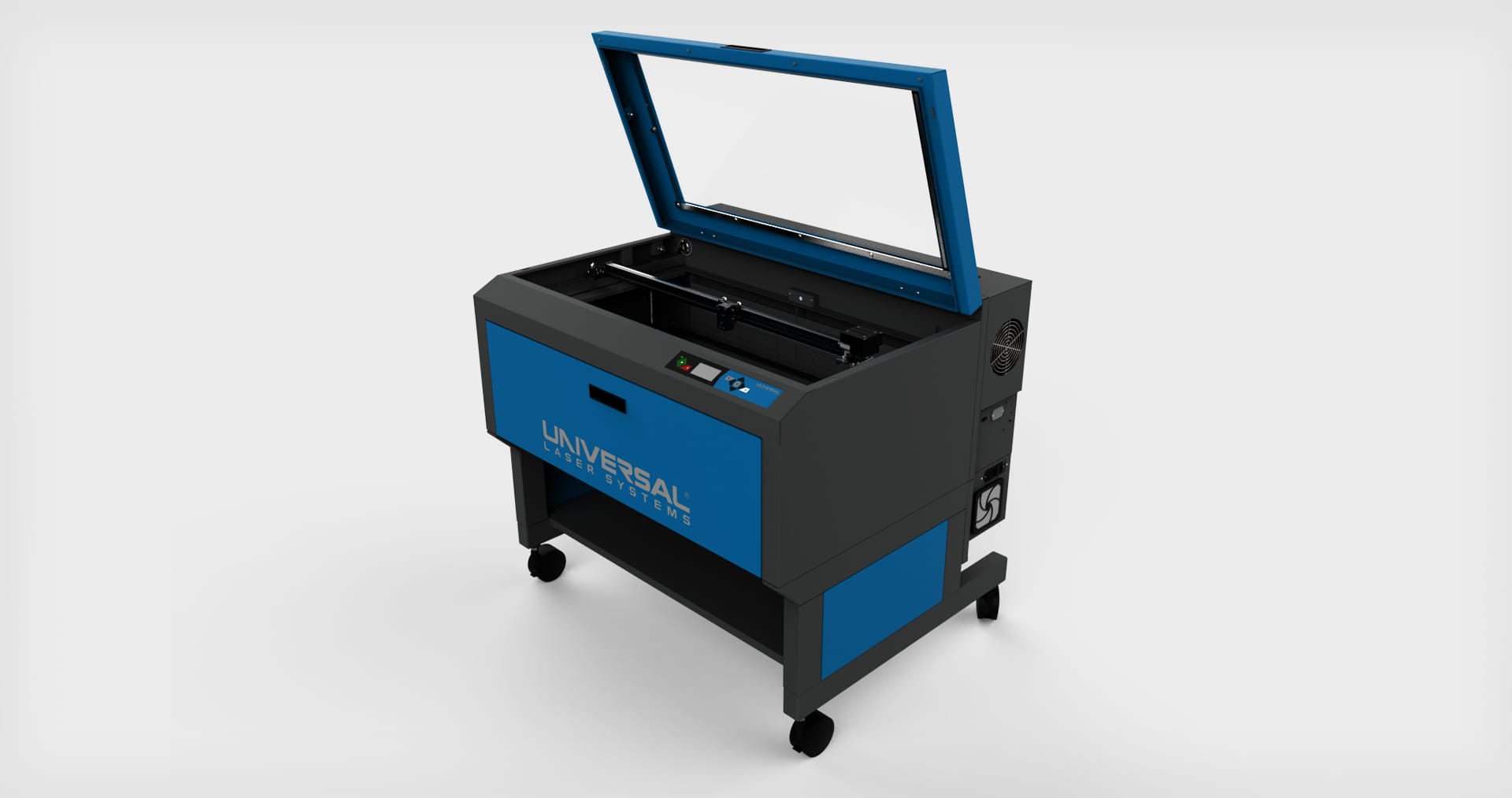

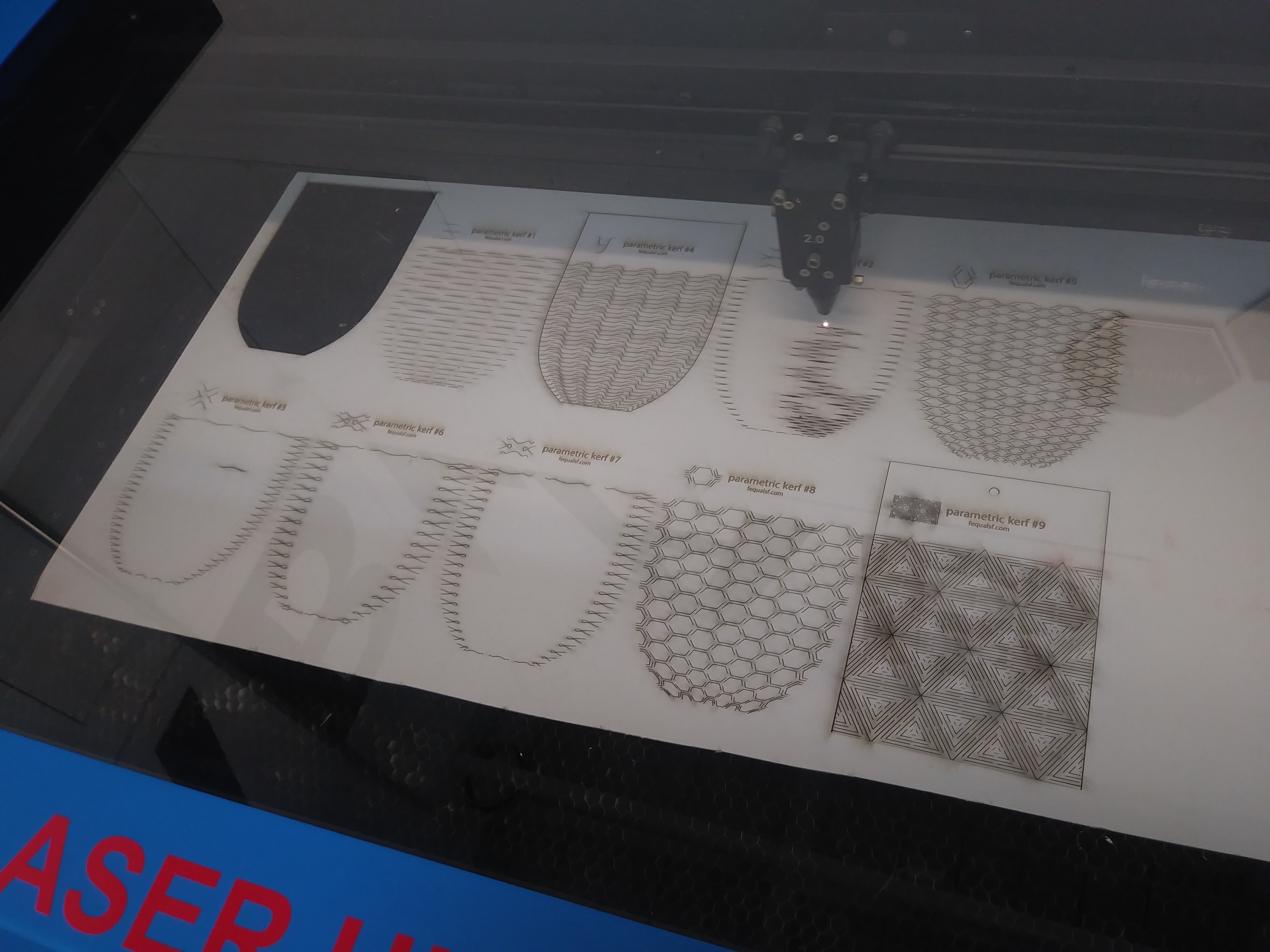

Laser Cutters

What is a Laser Cutter?

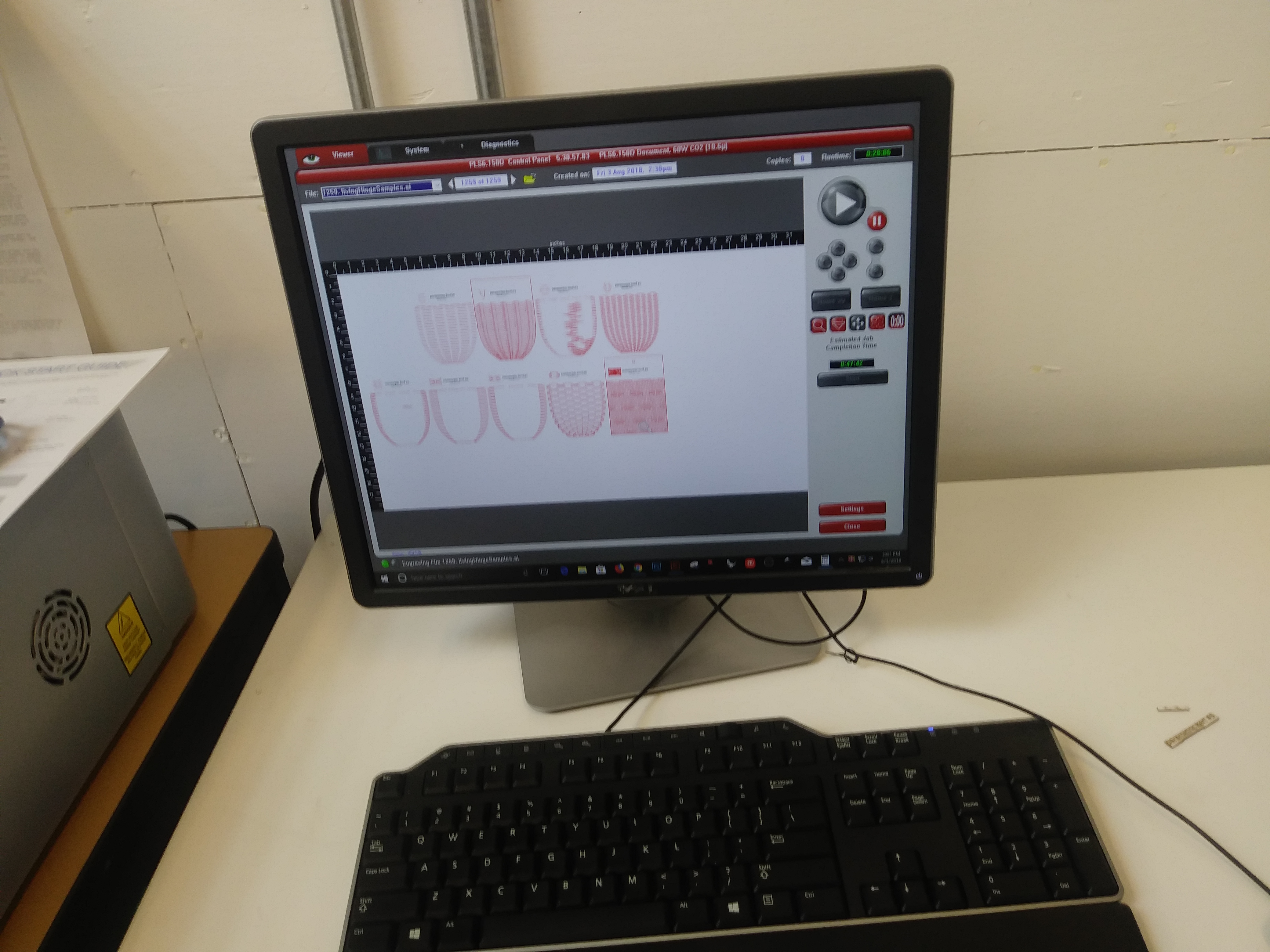

Laser cutting is a method of fabrication that uses a high-powered laser to cut or engrave a material. Modern laser systems are Computer Numerical Controlled (CNC) machines, meaning they receive a set of instructions from one or more computer programs that dictate where to cut and with how much intensity. We often refer to laser systems simply as laser cutters.

Tutorials and Online Resources

We will be doing an in-class learning activity to make a keychain. Once that is complete, you will use the following resources to advance your learning of Adobe Illustrator for laser cutting or graphic design.

- Go to Adobe’s tutorial website at https://helpx.adobe.com/illustrator/tutorials.html

- Starting with the top row of videos, watch and complete the tutorials titled “Create and edit shapes,” “Change color and strokes,” and “Add text to your designs.”

- Take a look at the rest of the tutorials on the page above. Choose any that interest you – logos, app icons, print images, and more are designed on Adobe Illustrator. Use this time to get a feel for some of the tools available in the program. You can also watch the following video if you would like to learn more about these tools: https://www.youtube.com/watch?v=UqjZR_v37K8

CNC Routers

What is a CNC Router?

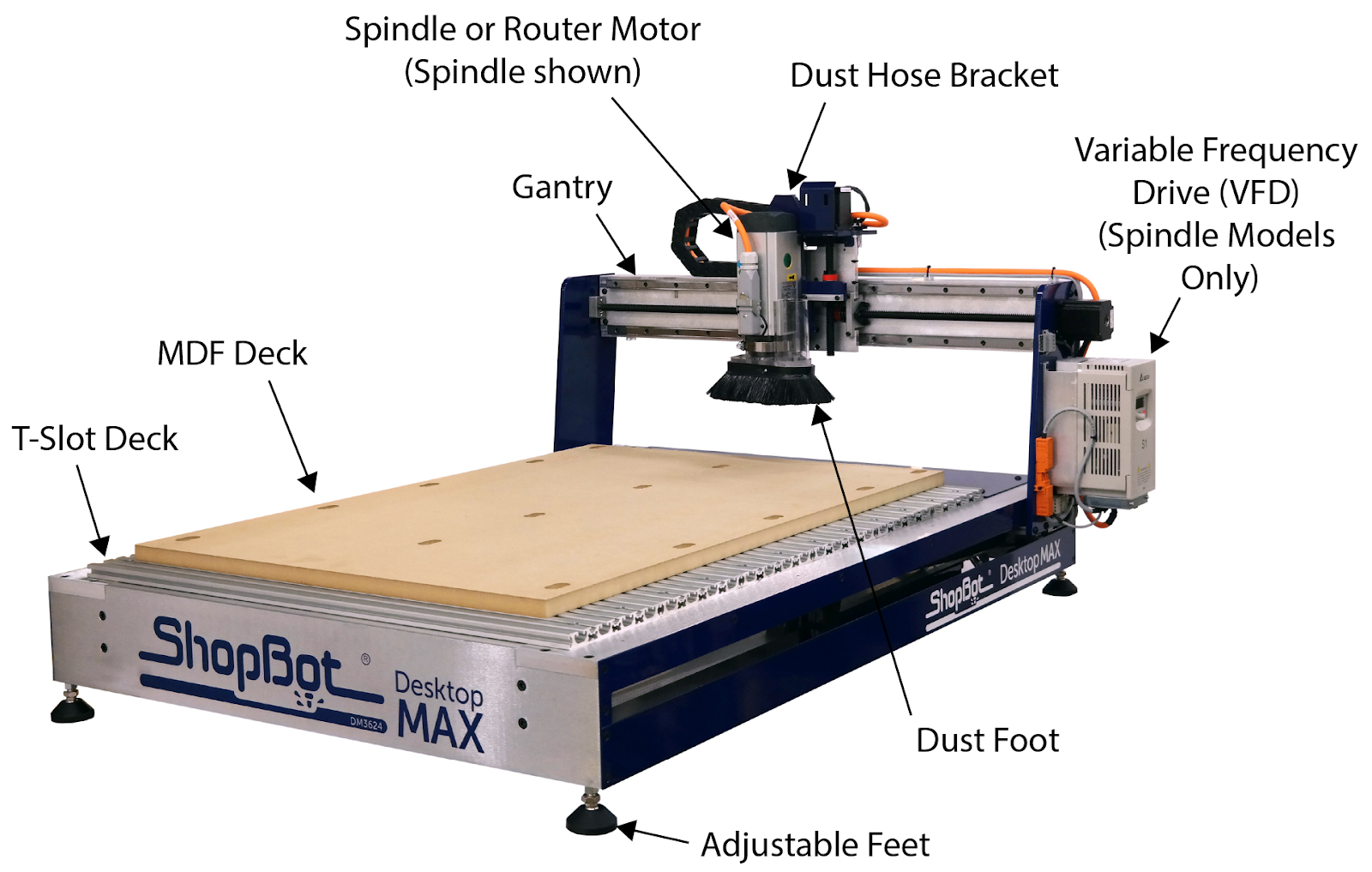

CNC Routing is a subtractive manufacturing technique that starts with a block or sheet of material which is cut down into a desired shape (as you would with a traditional mill, lathe, or chisel). A CNC Router consists of a Bed or Deck, where a material to be machined can be mounted, a spindel, which accepts a range of cutting bits and rotates them at high speeds, and a gantry system that allows the spindel to move in the X, Y, and Z axis , allowing it to carve out material in 3 dimensions. The CNC stands for Computer Numerical Control meaning that the movement of the spindle is not manually operated, but instead controlled by a program.

What Applications are there for CNC Routing?

Signage, Furniture, Cabinetry, Wood-working, metal component fabrication, plastic component fabrication, etc.

CNC Routers can cut a range of materials, from Plastic, to Wood, to Metals. They are much faster than additive manufacturing methods such as 3D Printing, and have the advantage of preserving the mechanical strength of the base material, but are limited in detail and geometry by the bit and angle of cut.